Selecting a suitable gasket for the UAE coast, i.e., in Abu Dhabi, and Sharjah, must be determined by the harsh marine conditions.

Coastal areas are affected by high humidity, saltwater environment, fluctuating temperatures, and corrosiveness of seawater.

In oil and gas, marine, desalination plants, construction, and power generation sectors, an improper selection of gasket causes equipment failure, leaks and lost downtime.

This guide will assist you in determining the most important factors to look for when choosing gaskets for UAE’s coastal regions and the remainder of the UAE, in addition to the best gasket materials and applications.

Why Gasket Selection Is Important in Coastal Regions

Gaskets are an essential element in closing fittings and avoiding leakage on pipelines, pumps, compressors, and other process equipment. In marine UAE environments, the environment promotes aging gaskets in the following ways:

- Corrosive salt air that promotes corrosion and degradation of materials.

- High humidity causing swelling or softening of some gasket materials.

- Extensive temperature fluctuations resulting from strong daytime sunlight to freezing nights.

- Endless contact with seawater for applications in marine and desalination plants.

Without a suitable gasket material, companies have increased maintenance expenses, safety risks, and unplanned downtime.

Points to Consider while Selecting Gaskets in UAE Coastal Regions

1. Corrosion Resistance

Salt and water are most corrosive towards metals and elastomers. Always use gaskets that are resistant to rust, chemical attack, and degradation. PTFE, graphite and quality stainless steel materials are better for the UAE coastal conditions.

2. Temperature and Pressure Ratings

Industrial uses in Dubai tend to feature high pressure pipes, compressors, or pumps. The gasket must be capable of resisting not only pressure but also highly elevated temperatures formed as a consequence of the environment and working conditions.

3. Media Compatibility

Regardless of application in seawater pipes, chemical processing, or oil and gas processing, the material should be chemically compatible with the fluid or gas being enclosed. EPDM gaskets, for instance, may find application in water but not in hydrocarbons.

4. Durability and Longevity

In places such as Jebel Ali Port, Fujairah and Ras Al Khaimah, equipment operates day and night in harsh conditions. The choice of resilient gasket materials reduces replacement requirements and optimizes working reliability.

5. Compliance to Industry Standards

The majority of industries in the UAE require gaskets that meet international standards such as ASME, API or ISO. Adherence avoids safety risks and meets regulatory requirements.

Best Gasket Materials for Coastal UA

One of the conventional products that still have applicability in sealing is the CAF Gasket, which is economical and compressible. Care should be taken to completely tally CAF gaskets in marine UAE environments because they have limited resistance to aggressive chemicals and seawater.

For applications that call for asbestos free substitutes, the CNAF Gasket is an option. Compressed Non Asbestos Fiber gaskets are commonly applied to pipelines, pumps and marine uses in hot, pressurized and corrosive media.

Exemplary sealing performance may demand exemplary materials such as the Graphite Gasket with attributes to resist severe temperatures and pressures. These are usually used in UAE power plants, refineries, and offshore oil rigs.

The second widely used alternative is the Non Asbestos Gasket Sheet, which is safe, eco friendly and yet extremely oil, fuel and seawater resistant. These sheets are utilized in green sealing operations by the majority of Dubai industries.

The Ring Joint Gasket is the sealing component utilized for Abu Dhabi oil and gas field operations and ocean rigs. Its metal to metal seal design offers superior performance at high pressure and temperature conditions.

Coastal UAE industrial equipment also utilizes the Rubber Gasket, commonly EPDM and Neoprene, that are highly seawater UV and weather resistant.

A Sheet of Rubber Gasket sheet is handy in case maintenance or tailoring is needed since it can be used with flexibility to cut and bend, something suitable for industries with rapid gasket replacement or tailored fitting.

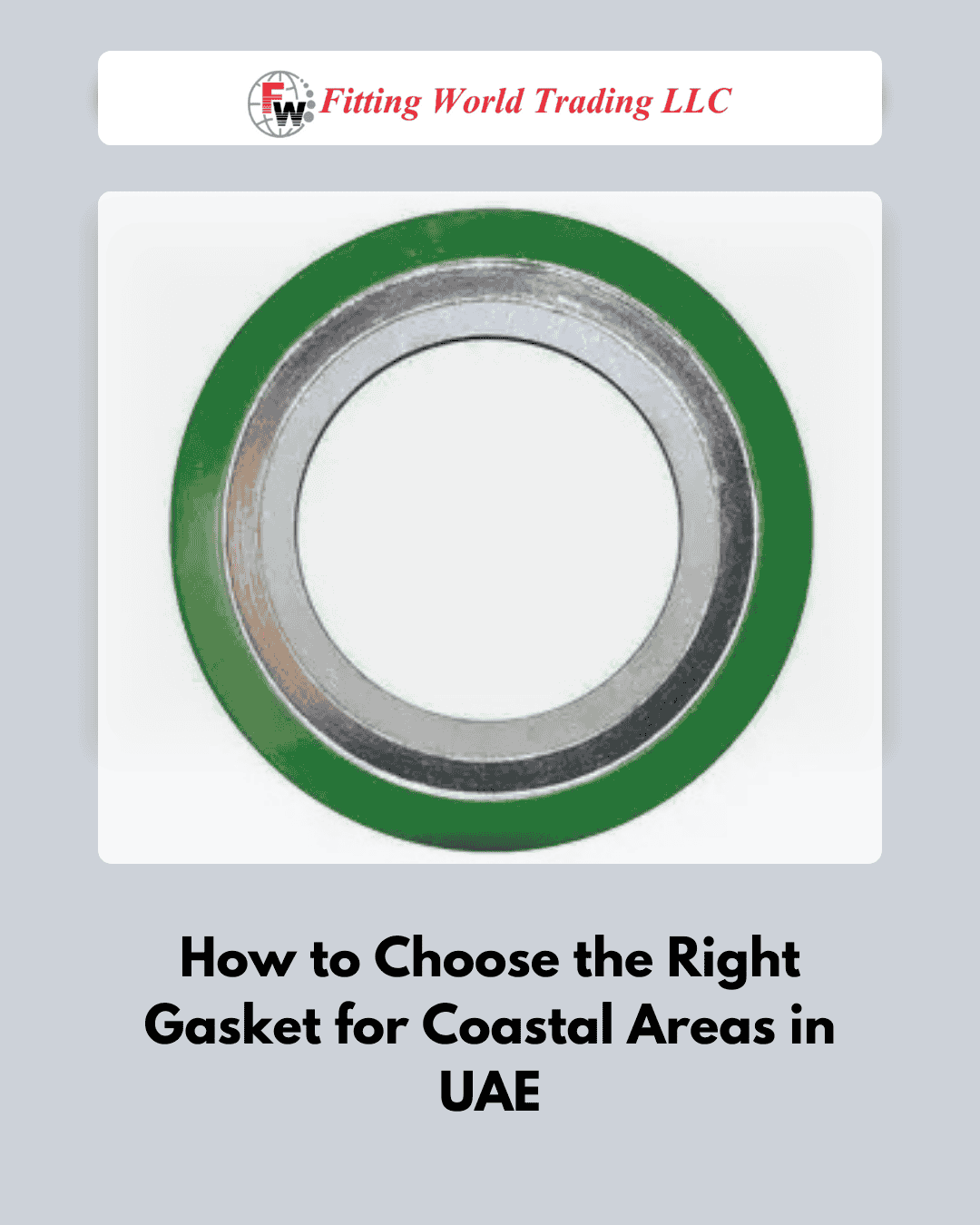

In Dubai high-pressure industrial pipelines and refineries, the Spiral Wound Gasket is most commonly used. Durability and resistance to harsh conditions by its metal and filler material make it a trustworthy choice for such stressful sealing.

Gasket Application Along the UAE Coast

In Dubai and the rest of the UAE coastal areas, durable gaskets are required across many industries:

- Marine and Shipbuilding: Gaskets used in pumps, engines and pipelines need to withstand seawater and vibration.

- Desalination Plants: EPDM and PTFE gaskets find extensive use in RO membrane systems and water treatment.

- Oil and Gas Industry: Graphite and metal gaskets provide safe sealing in harsh conditions offshore.

- HVAC and Construction: Rubber gaskets offer insulation, sealing, and vibration resistance in coastal-area facilities.

- Power Generation: Durable gaskets withstand leaks and ensure efficiency for power generation equipment subject to the coastal environment.

Practical Tips in Selecting the Correct Gasket in UAE

- Evaluate Environmental Conditions

Look at humidity, salinity, and temperature fluctuation prior to selecting the gasket material.

- Work with Local Suppliers

Working with gasket suppliers in Dubai ensures quicker delivery, UAE regulation compliance, and access to technical expertise.

- Make Use of High-Quality Materials

Investment in quality gaskets pays off in the long run through lowered maintenance and replacement.

- Schedule Periodic Maintenance

Regular servicing allows for timely identification of wear and guarantees gaskets are performing as designed.

- Specialized Gasket Solutions

For Abu Dhabi industrial complexes or Jebel Ali Free Zone industry, specially designed gaskets for the particular application work better than generic ones.

Localized Insight: UAE Market Trends

The emphasis of the UAE government on sustainable development, water security, and development of its oil and gas sector is driving the need for high-end sealing solutions.

As various desalination schemes are being undertaken and continual investment in maritime infrastructure takes place, UAE based gasket manufacturers increasingly provide eco friendly, long lasting and high performance gasket solutions.

Companies that invest in the right gasket technology not only reduce operational hazards but also contribute to maintaining industrial practices in the UAE.

Conclusion

Choosing the right gasket for coastal areas in the UAE is a strategic decision that directly impacts efficiency, safety, and long-term performance.

Whether for marine applications, desalination plants, oil and gas operations or construction projects, the gasket material must withstand the unique challenges of Dubai’s coastal environment.

By concentrating on corrosion resistance, durability, and compatibility, companies can make their sealing systems economical and dependable. Advising with expert gasket suppliers in Dubai as well as the entire UAE market is the most rational option to provide success in such extreme environments.

For companies in Dubai looking for trustworthy rescue solutions, FITTING WORLD TRADING LLC is the approved supplier of these invaluable rescue items.